Learn how to configure the Production & Order Pending Times in DecoNetwork so that your shop accurately calculates production due dates and customer delivery timelines. This enables your business to set realistic production schedules and provide customers with accurate delivery timelines. These settings apply globally by default. You can override these settings at the product group and individual product levels.

In this article

- Prerequisites

- Why production & order pending times matter

- How to configure production & order pending times

- Best-practice tips

- Troubleshooting production date issues

- Production & order pending times FAQs

- Additional resources

Prerequisites

- You must have administrator access to view and edit these settings

Configure Production & Order Pending Times

- Log into your DecoNetwork Website.

- Browse to Admin → Settings → Production & Order Settings.

-

Select Production & Order Pending Times.

The settings are displayed in the main work area.

-

Configure your settings:

-

Default production time defines how long it takes to complete production.

The number of Default Production Days is used to calculate due dates. When combined with shipping times, it uses the shipper's estimate to provide an estimated delivery date to customers.

Different decoration processes might have different production times. DecoNetwork allows you to set specific production days for each decoration process.

If you sell products without any decorations, you can specify the default production days for blank products.

The Calculate order estimated ship-by dates setting lets you choose how the ship-by dates are determined:

- Using process with longest production time: choose this option to use the decoration process with the longest production time to calculate the estimated ship-by date.

- Combining production time across all used processes: choose this option to combine the time across all processes used to calculate the estimated ship-by date.

Tip: If you have product groups or individual products with unique production needs, you can override these global defaults at those levels for finer control. -

Production Days - check the days of the week you carry out production activities. Unchecked days are not used in production time calculations.

-

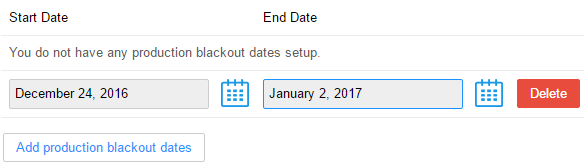

Production Blackouts are periods in which no production will take place, for example, a holiday period or planned maintenance periods. Click Add production blackout dates to make a new blackout period. Use the date picker to set the start and end dates. Click Delete to remove the blackout.

-

Default production schedule lets you specify the number of days before the shipping date that the Order is scheduled to be produced in.

Note: Unchecked production days and blackout dates directly affect due-date calculations. Make sure they reflect your real shop calendar. -

- Click Save when you're done.

Best-practice tips

- Align production days with your real shop schedule. Only select days when production actually occurs to avoid misleading due dates.

- Maintain blackout dates proactively. Add public holidays, planned shutdowns, or peak-season closures ahead of time to keep delivery estimates accurate.

- Use global settings as a baseline. Apply production time overrides at the product or product-group level only when production times genuinely differ.

- Review settings during busy periods. Reassess pending times before major sales events or seasonal spikes.

- Coordinate with shipping estimates. Production pending times work best when combined with accurate live or custom shipping methods.

Troubleshooting

Production or ship-by dates look incorrect

- Check that the correct production days are enabled.

- Confirm no unintended blackout dates are applied.

- Verify whether the order or product uses an overridden production time.

Orders appear to skip production days

This is expected behavior if a day is not selected as a production day or falls within a blackout period.

Customer delivery estimates don’t match internal expectations

- Ensure production pending times are realistic.

- Confirm shipping methods and transit times are correctly configured.

- Check whether the longest-process or combined-process calculation method is being used.

FAQs

Do production pending times affect existing orders?

No. Changes apply only to new orders created after the settings are saved.

Can I set different production times for specific products?

Yes. Production pending times can be overridden at the product or product-group level.

Are weekends automatically excluded?

No. Only the days you explicitly select as production days are included in calculations.

Do production pending times include shipping?

No. Production pending times calculate production only. Shipping estimates are added separately based on the configured shipping method.

Additional resources

- Configure production times for an individual product

- Configure production times for a product groups

Still have questions? Use the Search Tool at the top of the page to find more related guides. Need help? Click the icon to submit a support ticket—our Client Services team is ready to assist!

Comments

0 comments

Please sign in to leave a comment.