This article explains how to manage a product’s SKU codes, GTINs, and inventory settings from the SKU, GTIN & Inventory screen for a selected product in DecoNetwork.

On this screen, you can view and define SKU codes and GTINs for each product size or variant, as well as enable and manage inventory control. For products added from a supplier product catalog, DecoNetwork automatically adopts the supplier’s SKU codes and GTINs. For custom products, SKU codes and GTINs must be entered manually.

When inventory control is enabled, DecoNetwork tracks stock at the SKU level, generates purchase orders when inventory reaches low-level thresholds based on your settings, and sends low-stock warning emails to team members with Admin and Purchasing roles.

You can use the Inventory Management API to automate inventory management and increase productivity and accuracy. Please read the Inventory Management API help article for information on how to use the API and what settings can be controlled by the API.

In this article

- Prerequisites

- Why this screen matters

- How to access the SKU, GTIN & Inventory screen

- How to configure SKU, GTIN & inventory settings

- Inventory and product sizes

- Important note: size changes and inventory data

- Best-practice tips

- FAQs

- Troubleshooting

- Additional resources

Prerequisites

- You must have Administrator, Products, or Purchasing access to use this feature

- The product must already exist in your product list

Why this screen matters

The SKU, GTIN & Inventory screen controls how a product is uniquely identified and how its stock is managed. Correct configuration ensures accurate inventory tracking, reliable purchasing workflows, and timely low-stock alerts.

Inventory is tracked at the SKU level, meaning changes to sizes or SKU definitions directly affect how inventory quantities are stored and maintained.

How to access the SKU, GTIN & Inventory screen

- Log into your DecoNetwork Website.

-

Browse to Admin → Products.

-

Select the product you want to manage by either:

- Clicking on the product code.

- Clicking on the product name.

-

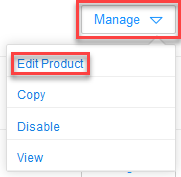

Clicking on the Manage button beside the product you want to configure, then selecting Edit Product.

The product properties will be shown in the main work area, with a menu at the left to select property categories. General will be selected by default.

-

Select SKU, GTIN & Inventory from the product properties menu.

The main work area contains the configuration options for SKU, GTIN, and inventory.

How to configure SKU, GTIN & inventory settings

- Review and configure the settings for the selected product as required.

-

Configure the Inventory Settings.

Inventory settings allow you to override the global out-of-stock behavior configured in Admin > Products > Inventory Settings.

- Use Default Inventory Settings: Choose this option to apply the standard out-of-stock behavior that has been configured globally in Admin > Products > Inventory Settings.

-

Specify Custom Inventory Settings: Choose this option to override the global out-of-stock inventory behavior. Select an option from the Out of stock behavior dropdown list:

- Allow adding to cart: Select this option if you want to allow customers to add out-of-stock products to their cart.

-

Do not allow adding to cart (check on-hand inventory): Select this option if you want to stop customers from adding out-of-stock products to their cart.

- This setting only applies to individual products with on-hand inventory tracking enabled. For instructions on how to enable inventory tracking globally, refer to the article, Configure Inventory Settings.

- Do not allow adding to cart (check supplier inventory): Select this option if you want to prevent customers from adding products to their cart that are out of stock in supplier inventory.

-

Do not allow adding to cart (check both on-hand and supplier inventory): Select this option if you want to prevent customers from adding products to the cart that are out of stock in both on-hand inventory and supplier inventory.

- Catalog products with on-hand inventory tracking enabled will check both on-hand and supplier levels. The on-hand inventory is checked first and if that is out of stock the system will then check supplier inventory level.

- Supplier inventory check applies to DecoNetwork catalog products from suppliers with live ordering enabled.

- Custom products with inventory tracking enabled will only check on-hand inventory levels.

- The system will hide products from blank product and decorated product lists if they are completely out of stock (across all SKUs) at both the local on hand inventory level and the supplier inventory level.

- Supplier inventory amounts can be viewed in the blank product SKU, GTIN & Inventory page and also in the Inventory On Hand page in Business Hub.

- Supplier out of stock threshold (consider out of stock if available quantity is below the entered quantity): This field allows you to specify the minimum supplier inventory level at which you want to allow customers to add products to cart. If the supplier inventory level is equal to or less than the specified amount, customers will not be able to add products to cart when using supplier inventory settings.

-

Configure the SKU Item Information

The Manage size/color combinations option allows you to control which size and color combinations are available for the product. Clicking on the link will bring up the Manage size/color combinations popup.

Choose an option from the dropdown box:

- Use supplier color/size combinations: Colors and sizes are available based on vendor stock.

- Don't limit color/sizes: All colors will be available for every size.

- Limit color/sizes: Enables the checkboxes so that you can choose specific size and color combinations.

-

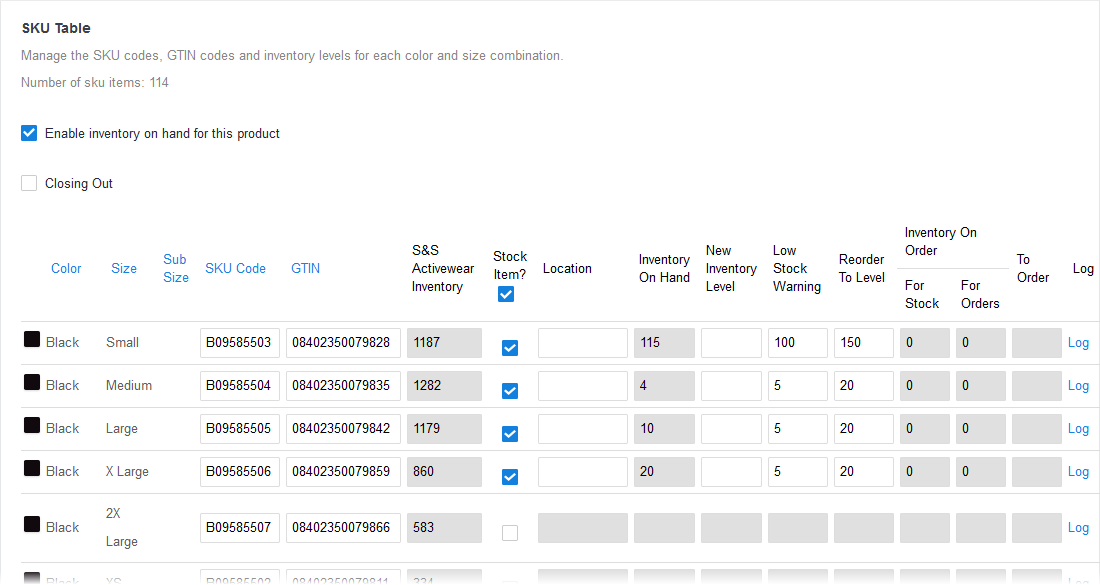

Configure the SKU Table

Tick the Enable inventory on hand for this product to enable inventory control for this product. When enabled, DecoNetwork tracks stock at the SKU level, generates purchase orders when stock reaches the configured low-level threshold, and sends low-stock warning emails to team members with Admin, Products, and Purchasing roles.

When the checkbox is ticked, the inventory columns for the SKU table are revealed.

- Color: Product color.

- Size: Product size.

- Sub Size: Additional size classification.

- SKU Code: Unique identifier for inventory tracking.

- GTIN: Globally Trade Item Number.

-

[Supplier Name] Inventory: Supplier stock level.

The supplier inventory amount will only be available if you have configured live ordering for catalog suppliers and Supplier Inventory Management for custom suppliers.

Click here for instructions on how to enable live ordering and supplier inventory management.

- Stock Item?: Enables inventory tracking for the SKU. The topmost checkbox will select all items on the page when ticked.

-

Location: lets you enter/edit the coordinate number of the storage bin where the item is physically located.

The location number will appear on the Production Worksheet, Purchase Order Stock Sheet, Order Inventory Pull Sheet, Packing Slips, and in the popup that appears when clicking on the Ordered or Received column while viewing the Production tab of an Order in Business Hub.

-

Inventory On Hand: current recorded stock level.

After you have changed the inventory level, an icon will be displayed beside the field.

Clicking on the icon will open the Inventory Change Reason popup, allowing you to enter a reason why the inventory level was manually changed.

- New Inventory Level: lets you make a correction to the Inventory On Hand level recorded if there is any discrepancy with the actual inventory level you have in stock.

- Low Stock Warning: lets you modify the inventory level at which a warning email will be sent to relevant team members informing them of the situation.

- Reorder To Level: lets you set the target inventory level that a purchase order will restock to.

-

Inventory On Order shows the present amount of the product that has already been ordered, but not yet received.

- For Stock: shows the number of inventory items on order for stock-keeping.

- For Orders: shows the number of inventory items on backorder to fulfill sales orders.

- To Order: shows quantity required to fulfill sales orders.

-

Log: opens a log window detailing events relating to the product in terms of inventory level.

SKU

Displays the SKU information of the product whose log you are viewing.

Inventory Event Log

Lists a log of events affecting the inventory level of the product. Events include:

- Restocked from purchase order: Restock of inventory from purchase order.

- Restocked from product import: Restock of inventory from product import.

-

Manually changed: Restock of inventory from manual entry.

If a reason was entered when the inventory level was changed, it will be displayed after the event name., e.g. Manually changed: Miscount.

- Allocated to Order: Depletion of inventory due to allocating products to an order.

- Unallocated from Order: Restock of inventory from a canceled order.

Current Purchase Orders

Lists the current purchase orders that are awaiting stock to replenish the product inventory to the required level.

-

Configure the Closing Out option.

The Closing Out option lets you choose whether to allow product items to be sold below recorded inventory levels.

-

Enabled: Products can only be sold until inventory reaches zero.

This means that customers will not be able to place orders for any SKUs that do not have inventory. This is useful if you have products on hand that are being discontinued and you want to prevent customers from ordering products that are no longer available after the last of your inventory has been sold.

Any SKU that does not have any recorded inventory will not be available for sale in the storefront. When a color is not available in the selected size, this will be indicated by stripes through the color selection block.

Existing orders that contain products marked for closing out will still raise a purchase order if a purchase order has not yet been raised for the products.

-

Disabled : Products can be sold below zero inventory.

This allows you to keep minimum stock on hand but still be able to sell the product when you have run out of stock.

-

-

- Click Save your changes.

Inventory and product sizes

Product sizes define the SKUs used for inventory tracking. Each size or variant represents a unique SKU with its own inventory record.

If a product has a single size (for example, ONE SIZE), that size represents the sole SKU used to store inventory quantities.

Important note: size changes and inventory data

Changing or removing sizes on a product with inventory control enabled will clear existing inventory data for the affected SKUs.

This includes scenarios where a product’s only size is changed (for example, changing ONE SIZE to ONE SIZE FITS ALL). Because this results in a new SKU being created, inventory quantities and inventory logs associated with the previous SKU are removed.

To help prevent accidental data loss, a confirmation message is displayed when attempting to delete or change sizes on products with inventory control enabled. This ensures you understand the impact before proceeding.

Best-practice tips

- Define SKU codes and GTINs before enabling inventory control.

- Avoid changing size structures on products that already have live inventory.

- Record or export inventory quantities before making size or SKU changes.

- Use consistent size naming to reduce the need for SKU restructuring.

Troubleshooting

Inventory quantities are missing

- Check whether the product’s size or SKU configuration was recently changed.

- Confirm that inventory control is still enabled.

- Review recent product edits in audit or request logs.

I did not intend to remove inventory

- Inventory removal occurs when SKUs change; this is expected behavior.

- Re-enter inventory quantities after reconfiguring the product.

FAQs

Does DecoNetwork automatically generate SKU codes and GTINs?

For products added from a supplier product catalog, DecoNetwork adopts the supplier’s SKU codes and GTINs automatically. For custom products, SKU codes and GTINs must be defined manually on the SKU, GTIN & Inventory screen.

Is inventory tracked per product or per size?

Inventory is tracked at the SKU level. Each product size or variant has its own SKU and its own inventory record.

What happens if I change a product’s size names?

Changing size names creates new SKUs. When this occurs, any existing inventory quantities and inventory logs associated with the previous SKUs are cleared.

Why do I see a warning when changing or deleting sizes?

A confirmation message is shown to prevent accidental inventory data loss. Changing or removing sizes affects the underlying SKUs and will clear existing inventory data for those SKUs.

Can inventory quantities be recovered after changing sizes?

No. Once SKUs are changed, previous inventory records cannot be restored. Inventory quantities must be re-entered manually for the new SKUs.

When are purchase orders generated?

Purchase orders are generated when inventory levels reach the configured low-stock threshold, provided inventory control is enabled for the product.

Who receives low-stock warning emails?

Low-stock warning emails are sent to users with Admin, Products, and Purchasing roles when inventory reaches the defined low-stock level.

Can I disable inventory control without losing SKU codes?

Yes. Disabling inventory control stops stock tracking and low-stock behavior but does not remove SKU or GTIN values.

Additional resources

- Configure Inventory Settings

- Inventory Management API

- How to Manage Product Inventory

- Use inventory tracking to trigger automatic stock replenishment

- How to enable on-hand inventory

Still have questions? Use the Search Tool at the top of the page to find more related guides. Need help? Click the icon to submit a support ticket—our Client Services team is ready to assist!

Comments

0 comments

Please sign in to leave a comment.